Daily problems and Maintenance of Labeling machinery

In the process of the rapid development of the pharmaceutical market, labeling machine also plays an increasingly important role in the pharmaceutical packaging industry. At present, the common labeling machines on the market include dry adhesive labeling machine, sleeve labeling machine, round bottle labeling machine, hot melt adhesive self-adhesive labeling machine, etc.

In the process of the rapid development of the pharmaceutical market, labeling machine also plays an increasingly important role in the pharmaceutical packaging industry. At present, the common labeling machines on the market include dry adhesive labeling machine, sleeve labeling machine, round bottle labeling machine, hot melt adhesive self-adhesive labeling machine, etc.But in the actual production process, the labeling machine will also encounter some small problems, so in order to better ensure the normal and stable operation of the work, users also need to know the common problems.

First, the label edge of the bottom paper cracking phenomenon.

Secondly, the label is rolled too tightly, which leads to adhesive leakage and label fracture.

Third, the peeling layer is damaged.

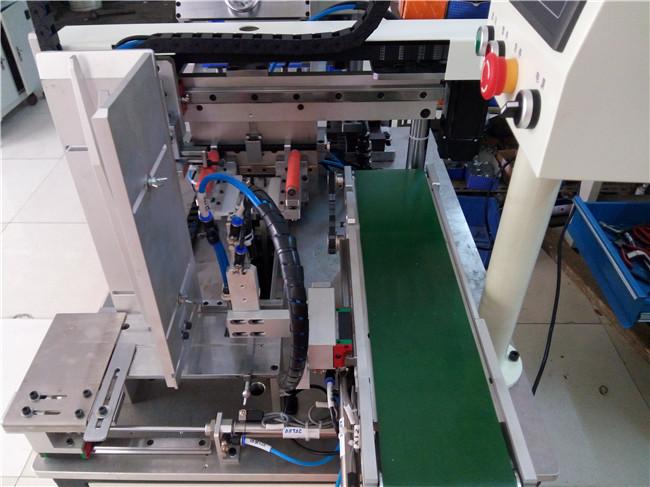

Understanding the common problems and solutions of the labeling machine is conducive to the timely maintenance of the equipment. However, in the process of using the labeling machine, regular maintenance of the equipment is also very important, which is the key to ensure the longevity and stability of the labeling equipment. It is understood that in general, after using the equipment, attention should be paid to keep clean, and the mechanism of the labeling machine equipment, such as friction roller, electrical box, should be cleaned to ensure the cleanliness of the next use and prevent pollution.

At the same time, users also need to do regular inspection and maintenance, in order to maintain the normal operation of the machine, including but not limited to: clean up waste paper and debris; Remove oil residue from drum and edge; Clean the sensor lens with a soft brush or cloth; Replace the fuse regularly. The equipment uses AC power supply, so the fuse should be used to prevent overload; Antirust, use antirust oil spray each stainless steel and iron parts, gently wipe with soft cloth, etc.