Description

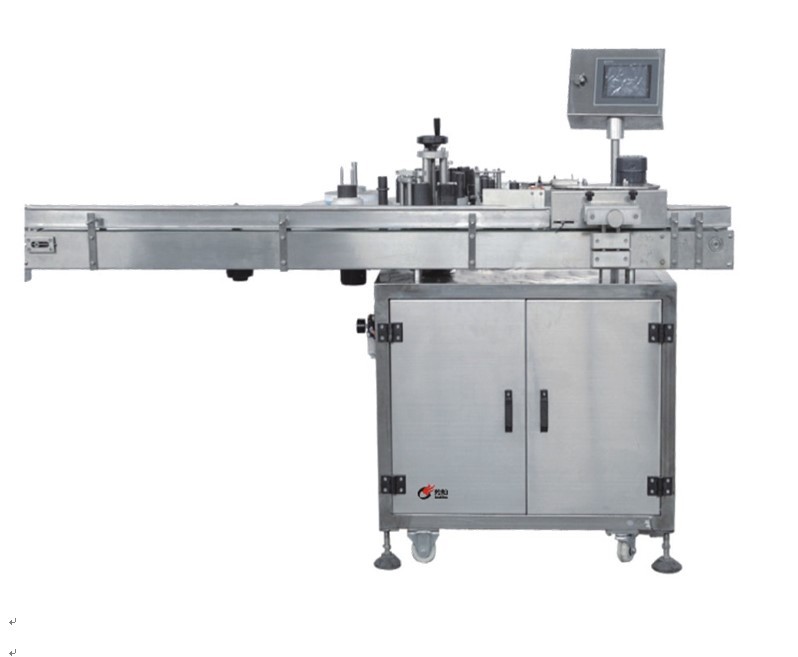

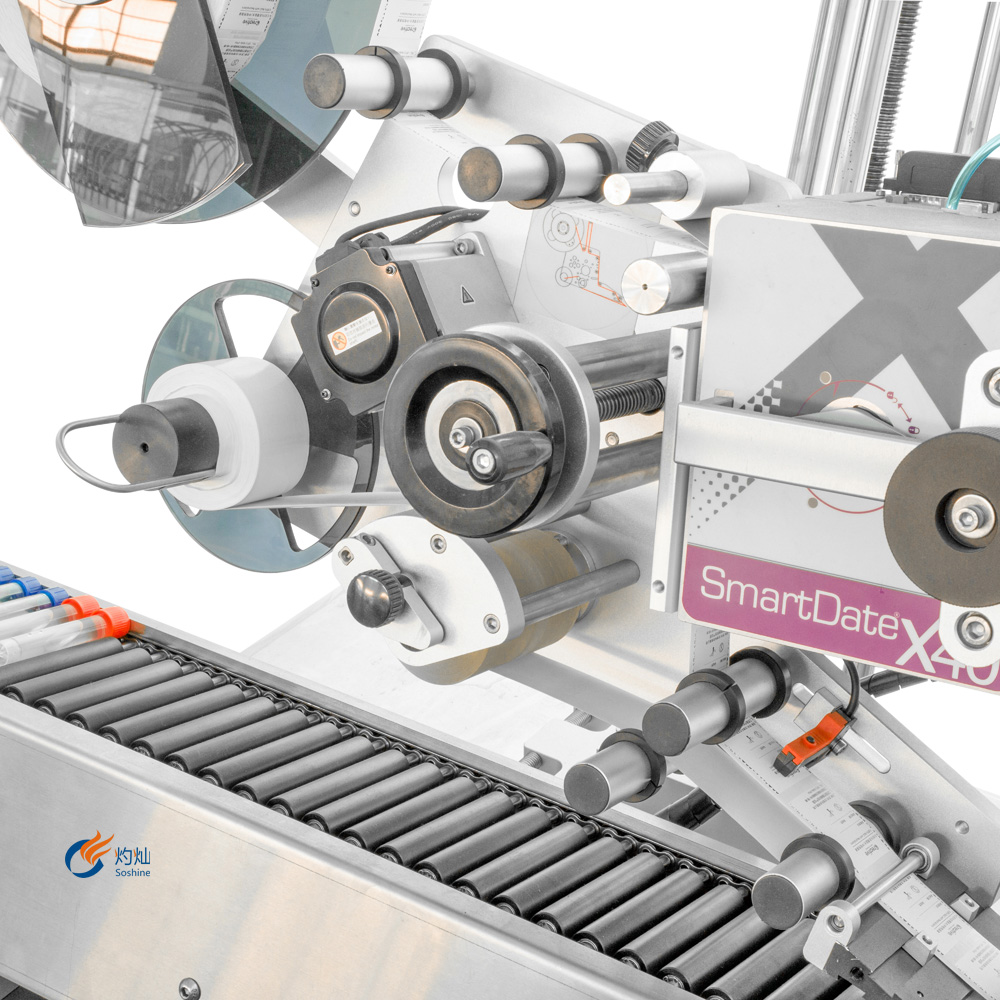

The label machine adopts vertical labeling and special top pressure device to ensure that the bottle body is not crooked. Using Japan Ainano servo motor, high speed labeling, accurate positioning, long-time stable work, greatly improve capacity, ensure product quality. Using Siemens programming controller and touch screen interface, simple operation, the production speed can be adjusted automatically, the abnormal condition can be monitored and displayed automatically, so that the operator can quickly eliminate the fault. Japanese pneumatic marking system is adopted, with clear and stable printing to meet the needs of high-speed labeling machine. When the bottles fall horizontally or accumulate on the conveyor belt, the machine will stop automatically, stop labeling automatically, reduce the waste of labels, and completely avoid the situation of broken bottles. Stop labeling and give an alarm when the label ribbon is used up.

The horizontal bottle feeding system is adopted to realize fragmentary bottles. The whole machine is made of SUS304 stainless steel and T6 aluminum alloy, which conforms to GMP. Rigorous production process management, has passed ISO9001 quality system certification.

After order placed,will offer drawing&can adjust based on client's requirement.

Application scope:

All kinds of flat bottles, square bottles, oval bottles, shaped bottles and other products of double-sided labeling. Suitable for food All kinds of bottle double-sided labeling operations in wine, chemistry, cosmetics and other industries.

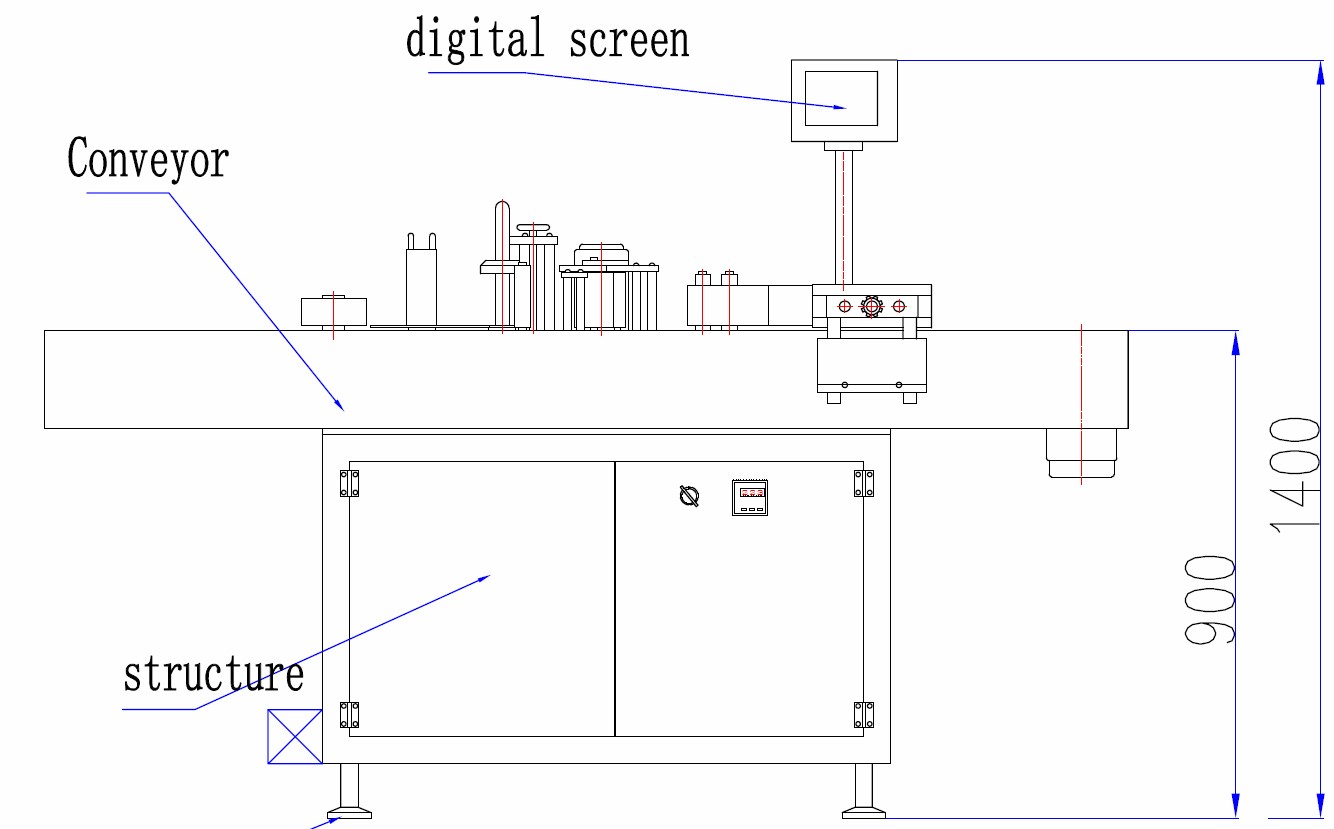

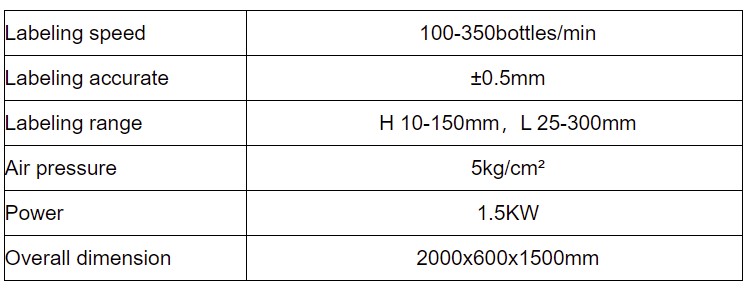

Specification

NOTE: ALL THE SPECIFICATION ABOVE COULD BE ADJUSTED ACCORDING TO CLIENT'S DIFFERENT ACTUAL DEMAND.WELCOME TO CONTACT US IF YOU HAVE REQUIREMENTS